Digital Printing - Questions

Digital Printing - Questions

Blog Article

Not known Incorrect Statements About Digital Printing

Table of ContentsDigital Printing Can Be Fun For EveryoneThe Ultimate Guide To Digital PrintingThe Best Guide To Digital Printing

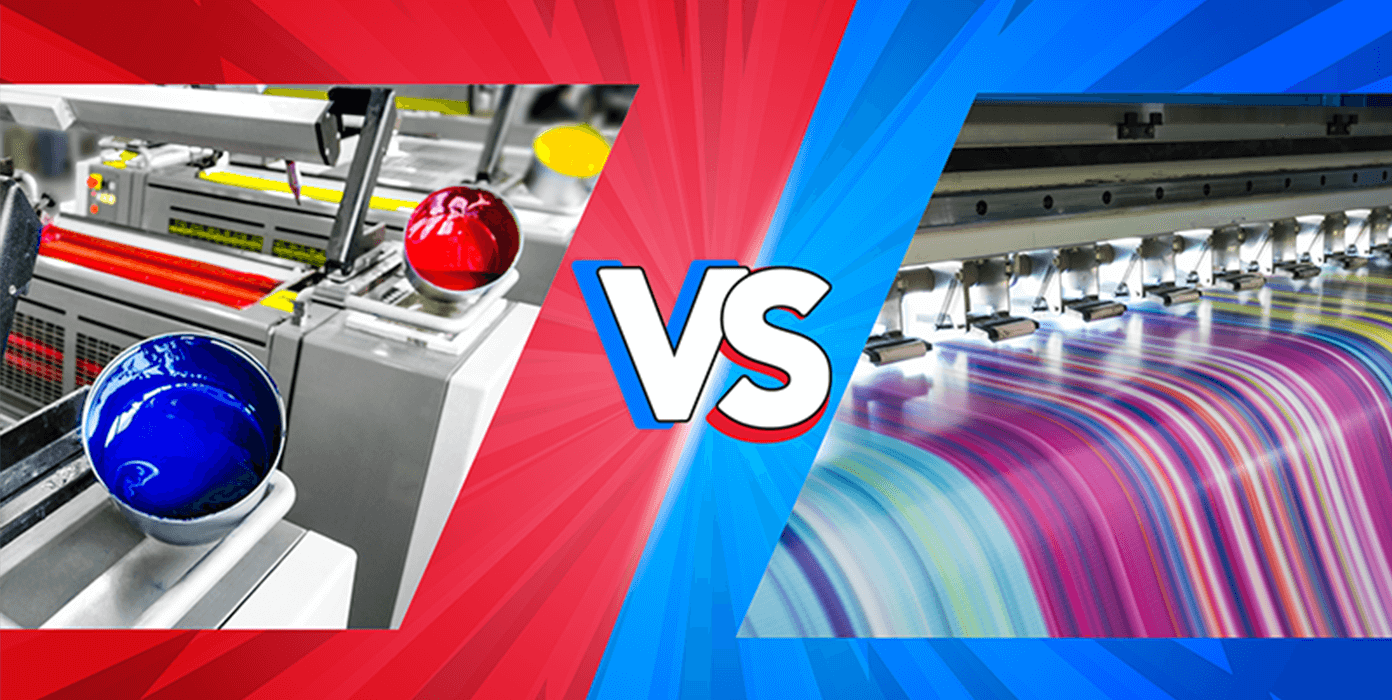

Standard printing methods like Offset Printing have been the standing quo for some time, and one of the largest factors is that at large quantities, it wins on price. That's if you prepare to use a solitary style for all of your packaging - those days are over.Offset Printing requires time and cash to develop a Printing Plate, while Digital Printing enables you to simply post an art data( as many as you desire )to the Press. Today, a lot of brands underuse print customization since they are simply not aware of the practice's feasible advantages and that digital printing is the way to obtain there.

. With digital printing, you have the power to create a make over for your screen every single time you require a new production run. If you require a single style for a whole campaign, then perhaps Litho is appropriate for you. Remember, your up front spending plan and lead time will certainly have to be taken right into consideration. Need assistance making a decision Bennett is a leading packaging and retail displays making business aiming to safeguard and promote our clients 'items with tailored corrugated options. We will partner with you every step of the means. With our totally integrated design-to-delivery process, we can be the solitary vendor resource. We are an award-winning producer of essentially anything corrugate.

We provide everything from ordinary brownish shipping boxes to advanced, high-graphic published point-of-purchase displays and every little thing in between. Digital Printing. They vary in size and technology, yet they enable you to upload art data straight to the press, rather of creating printing plates. Digital Printing is when you publish a digital-based image onto some type of print media.

Compared to traditional approaches, it permits a much more flexible printing design and enables you to develop special layouts for different product dimensions. This is just possible with Digital Printing, and it results in a new level of customization. Litho Lamination( Offset Printing)is a conventional printing technique and was one of the most popular selection until lately. Litho is the process of printing onto a paper liner board, and afterwards laminating that onto corrugated. The market is anticipated to hit a CAGR of 6. 45% over the projection period 20202025, according to a record by market research study firm ReportLinker. The sophisticated innovation electronic printing makes use of moderate solvents and much less dangerous chemicals than even more traditional printing approaches, such as offset and.

9 Easy Facts About Digital Printing Explained

solid ink. Therefore, with the increasing focus on environment-friendly sprinting and cost-efficient manufacturing, the need for digital printing remedies is expanding in the printed electronic devices market. Technical developments assisting digital printing have actually made sure reduced waste, maintaining the print high quality at the same level, the report adds. With the pros come some cons: The printing price is anticipated to take a toll, as digital is still a particular niche technique requiring print of shorter/customized batches. With major consumer-oriented suppliers progressively changing to tailored product packaging to enhance shelf-visibility and in turn bring in consumers, the adoption of digital printing is coming to be vital. The new T1190 will certainly be installed later on this year at a new Hummingbird site opening in Arizona. Hummingbird supplies a variety of digitally published corrugated product packaging solutions for food and beverage brands, consumer-packaged products and even more throughout North America. The department's electronic offerings consist of corrugated shelf-ready product packaging (SRP), food trays

large-format boxes, e-commerce solutions and volume screens (POP). Tetra Pak, a see this website Swedish-Swiss international food product packaging and handling firm, will start using full-color electronic printing on drink containers. Tetra Pak was expected to start digital printing in 2020, however the pandemic combated that. Thus, the firm expects to begin electronic manufacturing by third quarter this year at its Denton, Texas center. The company does things a little in a different way. They work extra in assisting their consumers to expand in consumer engagement and/or discovering brand-new channels.

and copyright at Tetra Pak, share their experiences with electronic services and what their companies supply. Digital print allows food and drink suppliers to run several package variations in the exact same print job, with virtually no added expenditure or production time. This versioning capability makes it feasible to create regionally details packaging or execute seasonal promos without large minimal orders. By offering full-color electronic printing on our beverage containers, it will reduce design-to-print time and permit a range of designs in one order. Digital printing offers a great deal of opportunity for CPGs to react to some market requires that we're seeing now. Before, the food industry for years has actually been comprised primarily on the very same product, same thinglike milk or juicehigh infiltration with very same product. Health and wellness has comes to be a central factor, new networks with shopping, much more affordable industries with other business and brand-new startups. We began to see an extra granular market. This includes complexity to the market; currently you have pop over here to create even more SKUs, or if a CPG concentrates on one product, they require to make certain they can get in touch with customers at an additional degree. It used to be CPGS would make a great item,

The Of Digital Printing

this process less complicated since you go from a digital layout directly to the printer, which can help a whole lot. You can also adjustlike if you obtain one or two days right into the packaging manufacturing or prior to the packaging and you need to transform one word or something, it's a lot much easier to make it take place.

Report this page